How to Select the Best Water Pipe Connector for Your Needs

Choosing the right water pipe connector is crucial for maintaining an efficient and leak-free water system. You might not realize it, but connection failures account for a whopping 35.14% of all issues in water supply networks. This often stems from design errors or improper conditions. To avoid such pitfalls, consider key factors like type, material, size, compatibility, performance, installation, and maintenance. For instance, a water pipe connector Hose Adapter fitting can offer flexibility and ease of use. By focusing on these elements, you ensure a reliable and long-lasting water system.

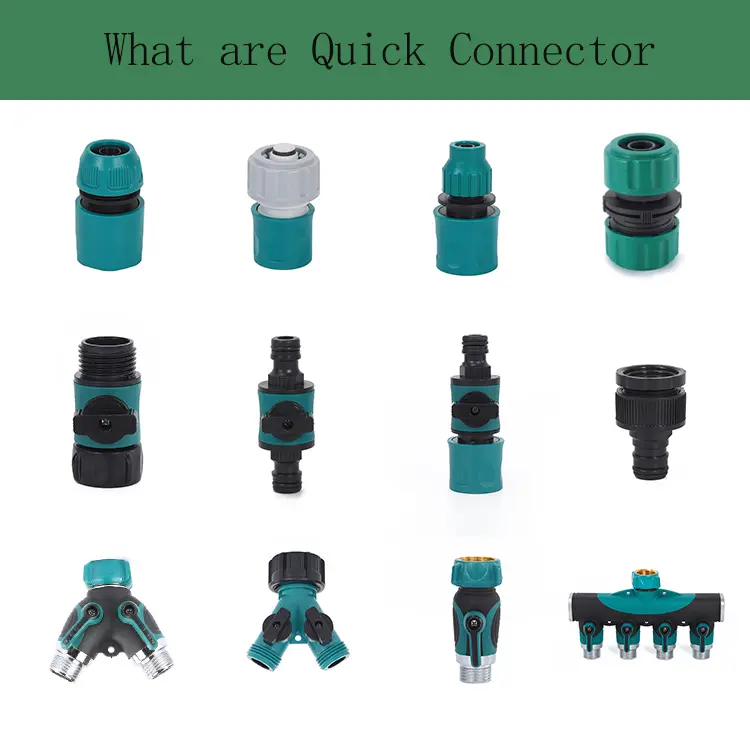

Types of Water Pipe Connectors

Choosing the right type of water pipe connector can make a big difference in your plumbing projects. Let's dive into some common types and see what they offer.

Quick-Connect Couplings

Quick-connect couplings are all about speed and convenience. You can attach and detach hoses in seconds without any tools. This makes them perfect for situations where you need to frequently connect and disconnect pipes. They work well in garden hoses and other applications where time is of the essence. Plus, they help prevent leaks by ensuring a snug fit every time.

Threaded Connectors

Threaded connectors are the classic choice for many plumbing systems. They use threads to secure the connection, which provides a strong and reliable seal. You often find these connectors in household plumbing, where durability is key. When using threaded connectors, make sure to apply plumber's tape to the threads. This helps prevent leaks and ensures a tight seal.

Barbed Fittings

Barbed fittings are great for flexible tubing. They have barbs that grip the inside of the tube, creating a secure connection. You typically use them in low-pressure applications, like irrigation systems or aquariums. To ensure a leak-free connection, you might want to use a clamp over the tubing. This adds an extra layer of security and keeps everything in place.

Each type of connector has its strengths. Consider your specific needs and choose the one that fits best. Whether you need quick changes, a strong seal, or flexibility, there's a connector out there for you.

Compression fittings offer a reliable way to connect pipes without the need for soldering or welding. You’ll find them especially useful when working with copper or plastic pipes. These fittings consist of three main components: a compression nut, a compression ring (also known as a ferrule), and the fitting body. When you tighten the nut, it compresses the ring against the pipe, creating a watertight seal. This method is not only practical but also versatile, making it suitable for various applications like plumbing, gas distribution, and HVAC systems.

One of the biggest advantages of compression fittings is their ease of use. You don’t need any special tools or skills to install them. Just a wrench will do the trick. This makes them an excellent choice for DIY enthusiasts or anyone looking to make quick repairs. Plus, they’re reusable. If you need to disconnect the pipes, simply loosen the nut and remove the fitting. This feature adds to their versatility and convenience.

Compression fittings are also known for their durability. They provide a strong mechanical connection that can withstand high pressure and temperature variations. This makes them ideal for both residential and commercial settings. Whether you’re installing a new faucet or setting up a complex plumbing system, compression fittings can handle the job.

Water Pipe Connector Hose Adapter Fitting

The water pipe connector hose adapter fitting is another essential component in your plumbing toolkit. It allows you to connect hoses to various types of pipes, providing flexibility and ease of use. These fittings are particularly handy when you need to adapt a hose to fit a different size or type of pipe. They come in various materials, including brass, plastic, and stainless steel, each offering unique benefits.

Brass adapters are known for their strength and resistance to corrosion, making them suitable for outdoor use. Plastic adapters, on the other hand, are lightweight and easy to handle, perfect for indoor applications. Stainless steel adapters offer the best of both worlds, combining durability with a sleek appearance.

When choosing a water pipe connector hose adapter fitting, consider the specific requirements of your project. Look at factors like the material, size, and compatibility with your existing system. This ensures a secure and leak-free connection. Also, think about the environmental conditions the fitting will face. For example, if it will be exposed to sunlight or chemicals, opt for materials that can withstand these elements.

Material Considerations

When selecting water pipe connectors, the material plays a crucial role in determining the durability and performance of your plumbing system. Let's explore some common materials and their benefits.

Brass Connectors

Brass connectors stand out for their strength and resistance to corrosion. You often see them in both residential and commercial plumbing systems. They handle high temperatures and pressures well, making them ideal for hot water applications. Brass also has a natural antimicrobial property, which helps maintain water quality. If you're looking for a reliable and long-lasting option, brass connectors might be your best bet.

Plastic Connectors

Plastic connectors offer a lightweight and cost-effective solution. They're easy to handle and install, which makes them perfect for DIY projects. You can find them in various types of plastic, such as PVC or PEX, each with its own set of advantages. PVC connectors are great for cold water systems, while PEX connectors provide flexibility and resistance to freezing. If you need a budget-friendly option that doesn't compromise on performance, consider plastic connectors.

Stainless Steel Connectors

Stainless steel connectors combine durability with a sleek appearance. They resist rust and corrosion, making them suitable for outdoor and industrial applications. Stainless steel can withstand extreme temperatures and pressures, ensuring a secure connection even in challenging environments. If you want a connector that offers both strength and style, stainless steel is an excellent choice.

When choosing the material for your water pipe connectors, consider the specific needs of your project. Think about factors like temperature, pressure, and environmental conditions. By selecting the right material, you ensure a reliable and efficient plumbing system.

Size and Compatibility

When it comes to selecting the best water pipe connector, size and compatibility play a crucial role. You want to ensure that your connectors fit perfectly with your existing system to avoid leaks and inefficiencies.

Measuring Pipe and Connector Sizes

First things first, you need to measure your pipes and connectors accurately. This step is essential to ensure a snug fit. Grab a tape measure or a caliper for precise measurements. Measure the diameter of the pipe's outer edge. This measurement will help you find a connector that matches perfectly.

- Tip: Always double-check your measurements. Even a small error can lead to a poor fit and potential leaks.

Once you have the measurements, look for connectors that match these dimensions. Most connectors come in standard sizes, so finding the right one shouldn't be too difficult. However, if you're dealing with non-standard sizes, you might need to look for specialized connectors.

Ensuring Compatibility with Existing Systems

Compatibility goes beyond just size. You also need to consider the material and type of your existing pipes. For instance, if you have PVC pipes, you'll want connectors that are compatible with PVC. Mixing materials can lead to corrosion or other issues over time.

- Pro Tip: Check the specifications of your current system. This information can guide you in choosing the right connectors.

Another aspect of compatibility is the system's pressure and temperature requirements. Some connectors, like hermetic connectors, offer superior resistance to extreme conditions. They provide airtight seals and maintain performance even under thermal shock. If your system operates under high pressure or extreme temperatures, opt for connectors designed to withstand these conditions.

Lastly, consider the environmental conditions your system faces. If your setup is outdoors, choose materials that resist rust and corrosion, like stainless steel. This choice ensures longevity and reliability.

By focusing on size and compatibility, you set the foundation for a leak-free and efficient water system. Remember, the right fit makes all the difference!

Performance Factors

When selecting a water pipe connector, you need to consider several performance factors. These factors ensure your system operates efficiently and reliably.

Pressure Ratings

Pressure ratings are crucial when choosing a connector. You want a connector that can handle the water pressure in your system. If you're using the connector for high-pressure tasks like power washing or outdoor cleaning, opt for one that supports high water flow. This choice prevents potential failures and ensures smooth operation.

- Tip: Always check the pressure rating on the connector's packaging. It should match or exceed your system's requirements.

- Sealing Performance

Sealing performance determines how well a connector prevents leaks. A good seal keeps your system leak-free and efficient. Look for connectors with features like O-rings or gaskets. These components enhance sealing and reduce the risk of leaks.

- Pro Tip: Regularly inspect seals for wear and tear. Replace them if necessary to maintain optimal performance.

- Durability and Longevity

Durability and longevity are key to a reliable water system. You want connectors that withstand daily use and environmental conditions. Materials like brass and stainless steel offer excellent durability. They resist corrosion and maintain their integrity over time.

- Consideration: Think about where you'll use the connector. If it's outdoors, choose materials that resist rust and weathering.

By focusing on these performance factors, you ensure your water system remains efficient and trouble-free. Remember, the right connector makes all the difference in maintaining a reliable setup.

Installation and Maintenance Tips

Easy Installation Practices

Installing water pipe connectors doesn't have to be a daunting task. With the right approach, you can ensure a secure and efficient setup. Here are some easy installation practices to follow:

-

Gather Your Tools: Before you start, make sure you have all the necessary tools. A wrench, plumber's tape, and a measuring tape are essential. Having everything on hand saves time and prevents interruptions.

-

Prepare the Pipes: Clean the ends of the pipes thoroughly. Dirt or debris can interfere with the connection and lead to leaks. Use a cloth or brush to remove any residue.

-

Use Plumber's Tape: Wrap plumber's tape around the threads of the connectors. This tape helps create a tight seal and reduces the risk of leaks. Make sure to wrap it in the direction of the threads for optimal results.

-

Tighten Securely: Use a wrench to tighten the connectors. Ensure they are snug but avoid over-tightening, which can damage the threads or the connector itself. A firm hand is usually enough to achieve a secure fit.

-

Test the Connection: Once installed, test the connection by running water through the system. Check for any leaks or drips. If you notice any, tighten the connectors a bit more or reapply plumber's tape as needed.

By following these steps, you can achieve a leak-free installation that stands the test of time.

Routine maintenance is key to ensuring the longevity and performance of your water pipe connectors. Here are some tips to keep your system in top shape:

-

Regular Inspections: Periodically check your connectors for signs of wear or damage. Look for cracks, corrosion, or any other issues that might compromise the connection. Early detection can prevent bigger problems down the line.

-

Clean the Connectors: Over time, mineral deposits or debris can accumulate on the connectors. Clean them regularly to maintain optimal performance. Use a mild cleaning solution and a soft brush to remove any buildup.

-

Monitor Pressure Levels: Keep an eye on the pressure levels in your system. High pressure can strain the connectors and lead to leaks. If you notice fluctuations, consider installing a pressure regulator to maintain consistent levels.

-

Replace Worn Parts: If you find any damaged or worn connectors, replace them promptly. Using compromised parts can lead to leaks and inefficiencies. Always have spare connectors on hand for quick replacements.

-

Protect from Environmental Factors: If your system is outdoors, protect the connectors from harsh weather conditions. Use covers or insulation to shield them from extreme temperatures or moisture.

By incorporating these maintenance practices into your routine, you can extend the life of your water pipe connectors and ensure a reliable water system. Remember, a little upkeep goes a long way in preventing costly repairs and maintaining efficiency.

You've explored the essentials of selecting the best water pipe connector. From understanding types and materials to ensuring size and compatibility, each factor plays a vital role. Remember these key points:

- Types and Materials: Choose connectors that suit your specific needs, whether it's quick-connect couplings or durable stainless steel.

- Size and Compatibility: Measure accurately and ensure compatibility with your existing system.

- Performance and Maintenance: Opt for connectors with high pressure ratings and maintain them regularly for longevity.

For personalized advice, consider consulting plumbing professionals like the experienced team at bluefrog Plumbing + Drain of West Houston. They can guide you in making informed decisions tailored to your system's requirements. By considering all these factors, you ensure a reliable and efficient water system.

Selecting Pipe Fittings Based on Accurate Dimensions

Tips for Picking the Perfect Handheld Spray Gun

Repair Connectors That Lengthen Your Car Wash Hose