In the ever-evolving world of gardening and irrigation, the choice of equipment can significantly impact efficiency and performance. Among the essential components of any irrigation system is the Plastic Hose Connector. These connectors play a crucial role in linking hoses and nozzles, ensuring a seamless flow of water for various applications. According to Dr. Emily Thorne, a leading expert in fluid dynamics and irrigation systems, "The right Plastic Hose Connector not only enhances the flexibility of your watering system but also prevents leaks that can lead to waste and inefficiency."

As homeowners and professionals alike seek to optimize their watering solutions, understanding the different types of Plastic Hose Connectors becomes imperative. With numerous options available on the market, choosing the best one tailored to specific needs can seem daunting. Factors such as durability, compatibility, and ease of use are critical considerations that will ultimately determine the success of your irrigation setup. In this guide, we will explore the top 10 Plastic Hose Connectors, aiming to empower users with the knowledge needed to make informed decisions and achieve their gardening goals effectively.

Plastic hose connectors, essential components in various industries, serve to ensure efficient fluid transfer while maintaining system integrity. With advancements in materials and design, modern plastic connectors exhibit superior durability, resistance to chemicals, and reduced weight when compared to their metal counterparts. According to a recent industry report from the Plastic Pipe and Fittings Association, the use of plastic connectors has surged by 20% in the last five years, highlighting their growing popularity in agricultural, irrigation, and landscaping applications. This trend underscores the importance of selecting the right connector for specific needs, considering factors such as pressure ratings, temperature limits, and compatibility with different fluids.

When choosing plastic hose connectors, it's crucial to consider application-specific requirements. For instance, connectors suitable for outdoors should offer UV resistance to prevent degradation. Additionally, ensure a snug fit with the hose; an ill-fitting connector could lead to leaks, which a study from the American Society of Mechanical Engineers indicates could result in significant fluid losses and increased operational costs.

Tips: Always check the compatibility of the connector with the hose material, especially when dealing with high-pressure systems. Additionally, consider employing additional sealing measures or clamps to enhance leak prevention, particularly in applications exposed to vibrations or movement.

This bar chart illustrates the durability ratings of various plastic hose connectors, helping you in choosing the best one based on their performance.

When choosing plastic hose connectors, there are several key features to consider that can significantly impact performance and usability. First and foremost, the material quality is crucial. Opt for connectors made from durable plastics that can withstand weather elements and resist degradation over time. Consider connectors with UV resistance if they will be exposed to sunlight, as this can prevent brittleness and extend their lifespan. Additionally, the temperature range of the material is important to ensure it performs well in various environments, whether it’s for gardening, industrial use, or home applications.

Another vital aspect to evaluate is the connector's design and compatibility. Look for options that offer a secure fit with your existing hoses to minimize leaks and ensure efficient water flow. Features such as ergonomic grips or easy-to-use locking mechanisms can greatly enhance user experience, especially when frequent connections and disconnections are necessary. Lastly, examine the versatility of the connectors; those that can be adapted to different hose sizes or equipped with additional features, like quick couplings or adjustable nozzles, can provide greater flexibility for varied tasks. These considerations will help you select the best plastic hose connectors for your specific needs.

When selecting plastic hose connectors, it is essential to delve into detailed reviews and comparisons to identify the most suitable options for your specific needs. A great connector should ensure a secure and leak-proof connection, while also being durable enough to withstand various environmental conditions. The material quality, ease of installation, and compatibility with different hose sizes and types play a significant role in the overall effectiveness of these connectors.

Comparing different models based on user reviews provides valuable insights into reliability and performance. Some connectors may excel in high-pressure applications, while others may be more suited for garden hoses or light-duty usages.

It's also worthwhile to consider the connector's design features, such as ergonomic grips or quick-release mechanisms, which can enhance usability. By examining these factors, individuals can make informed decisions and invest in connectors that will meet their functional requirements reliably and efficiently.

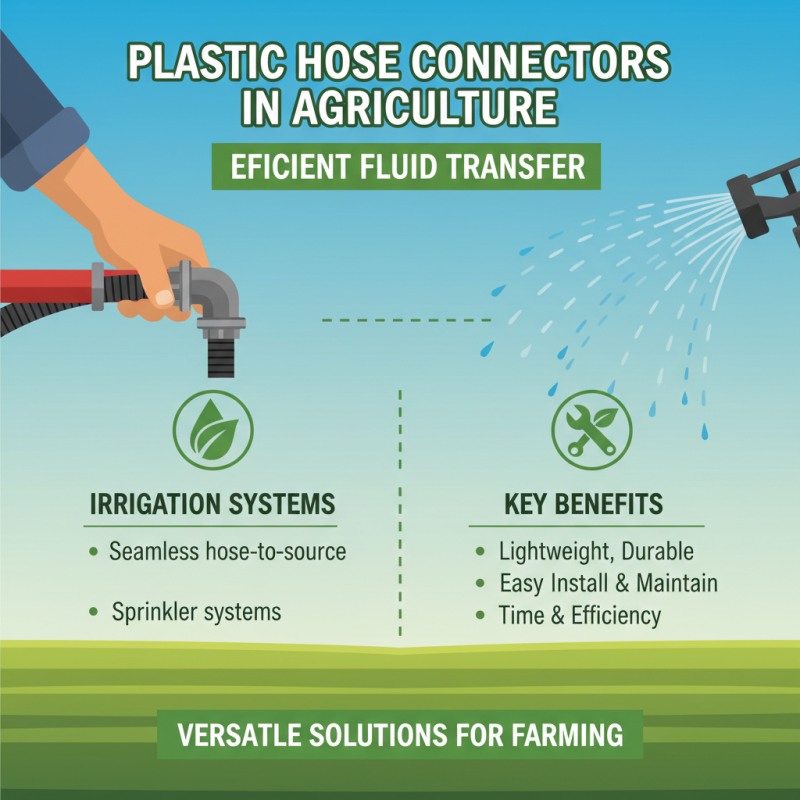

Plastic hose connectors play a crucial role across various industries, offering versatile solutions for fluid transfer and management. In agriculture, these connectors facilitate efficient irrigation systems, enabling farmers to connect hoses to water sources or sprinkler systems seamlessly. Their lightweight yet durable nature allows for easy installation and maintenance, which is essential in the field where time and efficiency are of the essence.

In the automotive sector, plastic hose connectors are commonly used in cooling and fuel systems. They provide reliable connections that withstand changing temperatures and pressures, reducing the risk of leaks and breakdowns. Additionally, in the manufacturing industry, these connectors are integral to conveyor systems and machinery, ensuring smooth fluid flow and operational efficiency. The flexibility and resistance to corrosion make them suitable for various manufacturing processes, ranging from chemical handling to general fluid delivery.

When it comes to maximizing the longevity and performance of plastic hose connectors, regular maintenance is key. According to a report by the American Society of Mechanical Engineers, approximately 30% of hose failures can be attributed to improper maintenance and lack of inspection. To prevent such failures, users should regularly check for signs of wear or damage, such as cracks or discoloration. Keeping connectors clean and free of debris not only enhances their operational efficiency but also extends their lifespan significantly. A simple rinse with water after each use can prevent buildup that might compromise the integrity of the connectors over time.

Additionally, proper storage can greatly impact the durability of hose connectors. The Hose Manufacturers Association recommends storing them in a cool, dry place to protect them from UV exposure and extreme temperatures, which can lead to degradation of the plastic material. Using protective caps when connectors are not in use can also help shield them from physical damage and contamination. Implementing these maintenance tips can result in a notable increase in the performance of hose connectors, leading to minimized downtime and reduced replacement costs. Regular audits of equipment can further aid in identifying potential issues before they lead to significant failures, ensuring that the connectors operate at their peak efficiency.

| Connector Type | Material | Diameter (inches) | Max Pressure (psi) | Temperature Range (°F) | Recommended Applications |

|---|---|---|---|---|---|

| Barbed Connector | PVC | 3/4 | 60 | 32-140 | Garden hoses, irrigation |

| Quick Connect | Polypropylene | 1 | 80 | 32-140 | Pressure washing, air compressors |

| Threaded Connector | Nylon | 1/2 | 100 | 50-180 | Industrial applications, pneumatic systems |

| Push-fit Connector | ABS | 3/4 | 60 | 32-150 | HVAC systems, water supply |

| Compression Fitting | PVC | 1 | 70 | 40-160 | Plumbing connections |

| Garden Hose Connector | Brass-Plated | 5/8 | 50 | 32-120 | Home gardening, sprinklers |

| Barrel Connector | HDPE | 1 1/4 | Late April-80 | Rain barrels, outdoor water collection | |

| Inline Filter Connector | Polypropylene | 1/2 | 60 | 32-140 | Water filtration systems |

| Teflon Tape Connector | Teflon | 1 | 40 | 50-150 | Sealing connections to prevent leakage |

| Drip Irrigation Connector | PVC | 1/4 | 30 | 32-120 | Agricultural drip irrigation systems |