In the realm of fluid management, the efficiency of systems heavily relies on the proper use of components such as hoses and hose connectors. Hose connectors play a crucial role in ensuring the seamless transmission of liquids and gases across varied applications, ranging from industrial processes to everyday household tasks. According to a recent report from the Fluid Power Journal, the global market for hose fittings, including connectors, is projected to reach $3.5 billion by 2027, indicating a sustained demand driven by sectors like manufacturing, agriculture, and construction.

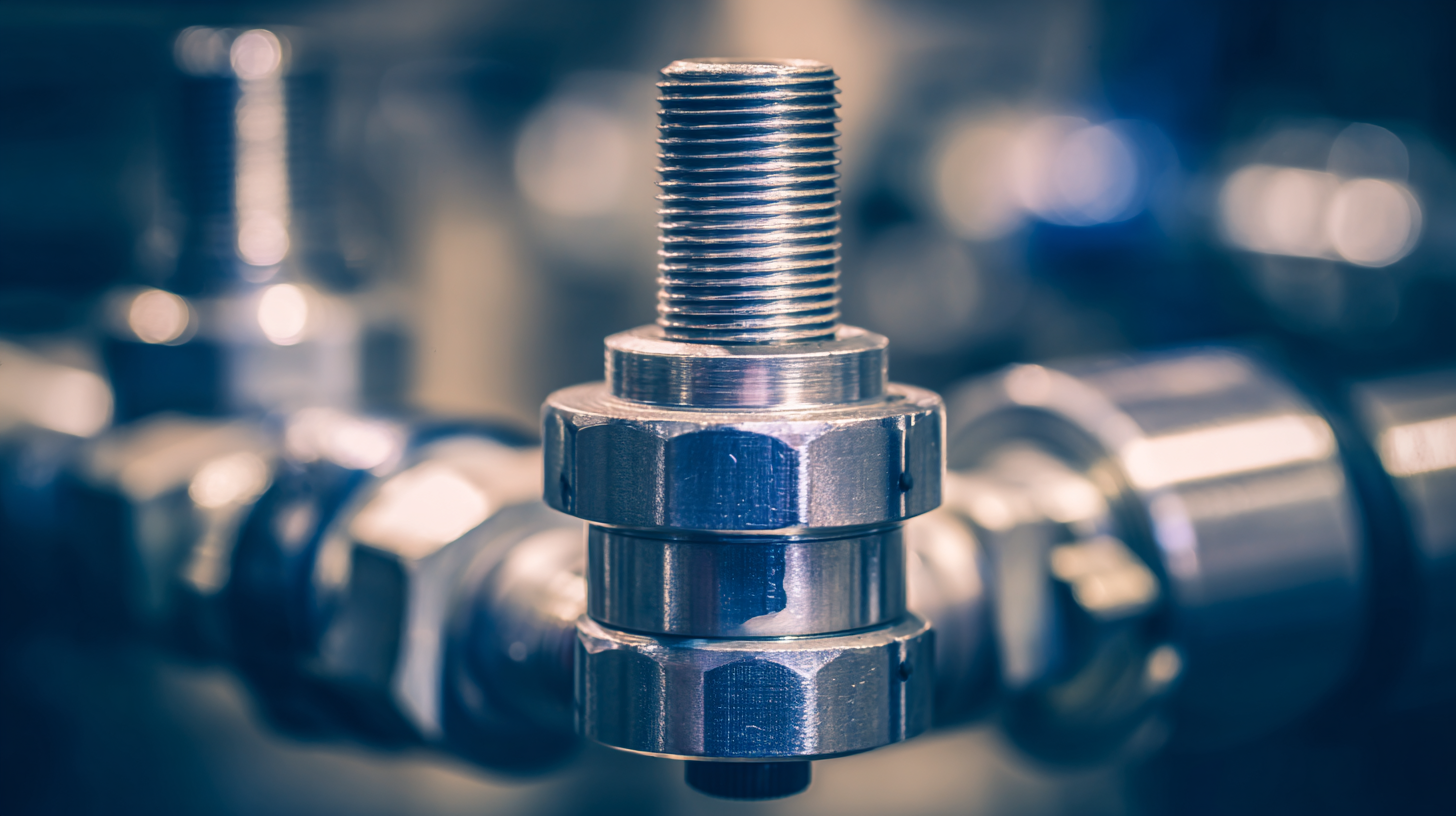

The versatility of hose connectors is further underscored by their diverse types, each designed to cater to specific needs and environments. From quick-disconnect fittings to barbed and threaded connectors, these components are engineered to enhance performance, minimize leaks, and improve safety during fluid transfer operations. As fluid management systems continue to evolve, understanding the benefits and applications of different hose connector types becomes imperative for professionals aiming to optimize their operations and maintain compliance with stringent regulatory standards. With the right hose connector, businesses can not only enhance operational efficiency but also contribute to sustainability efforts by reducing waste and energy consumption.

The versatility of hose connectors is further underscored by their diverse types, each designed to cater to specific needs and environments. From quick-disconnect fittings to barbed and threaded connectors, these components are engineered to enhance performance, minimize leaks, and improve safety during fluid transfer operations. As fluid management systems continue to evolve, understanding the benefits and applications of different hose connector types becomes imperative for professionals aiming to optimize their operations and maintain compliance with stringent regulatory standards. With the right hose connector, businesses can not only enhance operational efficiency but also contribute to sustainability efforts by reducing waste and energy consumption.

Hose connectors play a crucial role in fluid management across diverse industries, enabling seamless fluid transfer and maintaining system integrity. There are several types of hose connectors, each designed with specific materials and configurations to cater to various applications. Common types include barbed fittings, camlock couplings, and threaded connectors, with choices primarily driven by factors such as pressure ratings, chemical compatibility, and ease of assembly. According to a report by MarketsandMarkets, the global hose and fittings market is projected to reach USD 25.6 billion by 2025, highlighting the growing demand for efficient fluid management solutions.

Materials commonly used for hose connectors include brass, stainless steel, plastic, and rubber, each offering unique advantages. For instance, brass connectors provide durability and resistance to corrosion, making them ideal for harsh environments, while PTFE-lined connectors are preferred when dealing with aggressive chemicals. The design also plays a significant role; for example, camlock fittings allow for quick disconnects, which significantly reduces downtime in operational processes. As the industry evolves, manufacturers continue to innovate, developing connectors that enhance performance while ensuring safety and reliability in various applications.

In fluid management systems, hose connectors play a crucial role in ensuring efficiency and reliability. The use of high-quality hose connectors not only streamlines the transfer of fluids but also significantly reduces the risk of leaks and contamination. According to a report by MarketsandMarkets, the global market for fluid management systems is expected to reach $41 billion by 2026, highlighting the increasing demand for effective and durable connectors. These components allow for quick assembly and disassembly, facilitating maintenance and reducing downtime in industrial operations.

The benefits of using hose connectors extend beyond mere functionality. They enhance the overall safety of fluid management processes by minimizing the chances of fluid spills, which can lead to environmental hazards and costly clean-up operations. Additionally, specialized connectors can withstand high pressures and harsh temperatures, thereby improving system durability and performance. The International Fluid Power Society estimates that effective fluid management can boost efficiency by as much as 20%, making the adoption of superior hose connectors a strategic investment for many industries.

This chart illustrates the various benefits of using hose connectors in fluid management systems. Each benefit is represented in percentages, demonstrating the key advantages such as ease of use, leak prevention, pressure resistance, versatility, and cost efficiency.

Hose connectors play a vital role across various industries by facilitating safe and efficient fluid management. In agriculture, for instance, hose connectors are essential for irrigation systems, allowing farmers to distribute water or fertilizers effectively across their fields. These connectors enable quick changes in equipment and support the seamless transfer of liquids, ensuring that crops receive the nourishment they need for optimal growth.

When selecting a hose connector for fluid management, several key factors must be taken into account to ensure optimal performance and reliability. Compatibility with the hose material is crucial, as using a connector designed for PVC hoses with rubber hoses can lead to leakage or system failure. According to a report from the Fluid Power Journal, around 30% of fluid management issues arise from improper connector selection, underscoring the importance of material compatibility.

Another significant consideration is the pressure rating of the hose connector. Different applications demand specific pressure ratings to handle varying fluid dynamics safely. The Industrial Hose Association indicates that choosing a connector with a lower pressure rating than required can lead to catastrophic failures or safety hazards in high-pressure environments. Additionally, the environmental factors, such as temperature extremes and exposure to chemicals, can impact connector longevity and should guide the selection process to enhance reliability and reduce maintenance costs.

| Type of Hose Connector | Benefits | Common Applications | Factors to Consider |

|---|---|---|---|

| Barbed Connectors | Secure grip on hoses, simple installation | Water supply lines, irrigation | Hose size compatibility, material type |

| Threaded Connectors | Strong connection, leak-proof | Hydraulic systems, industrial use | Thread pitch, material strength |

| Quick Disconnect Couplings | Easy to attach and detach, time-efficient | Agriculture, automotive | Pressure rating, connection type |

| Camlock Fittings | Quick connection, fumeless operation | Chemical transfer, food processing | Handling requirements, chemical compatibility |

| Push-on Connectors | Simple installation, low-cost | Air and water lines | Hose material, application pressure |

When it comes to hose connectors, ensuring optimal performance is crucial for effective fluid management. Proper maintenance not only extends the lifespan of these connectors but also prevents issues such as leaks and reduced water pressure. According to industry research, nearly 30% of water wasted in home gardens results from improper hose management, emphasizing the importance of reliable connectors. To keep hose connectors functioning efficiently, regular inspections for wear and tear are essential. Look for signs of cracking or damage and replace any components as necessary.

Cleaning the connectors is another vital maintenance tip. Dirt and debris can easily clog the connection points, leading to reduced performance. A report from the Fluid Power Journal indicates that routine cleaning can enhance flow rates by up to 15%. Additionally, lubricating the threads of hose connectors can help prevent them from seizing, making disconnections easier while maintaining a tight seal. Following these maintenance tips can help you avoid common pitfalls and ensure that your hose connectors deliver optimal performance every time.