Choosing the right Hose Connector is crucial for achieving efficient fluid transfer. John Smith, a leading expert in hose technology, once stated, “The right connector makes all the difference in performance.” He understands that not all connectors work for every application.

In the world of hose connectors, various types exist. Each has unique features tailored to specific needs. Some are designed for high pressure, while others serve low-pressure tasks. This complexity can be overwhelming. It’s essential to assess your requirements carefully. Consider factors like temperature and pressure ratings.

Ignoring these details can lead to leaks or failures. You might purchase a connector that doesn’t fit. Such mistakes waste time and money. The key is research. Not every hose connector is versatile. A well-informed choice prevents future issues and ensures reliability in your tasks.

Choosing the right hose connector can significantly impact your gardening or industrial tasks. The market offers various types of hose connectors designed for different applications. Understanding these options is crucial.

There are three main types of hose connectors:

push-fit,

threaded, and

snap-on.

Push-fit connectors provide ease of use. They require no tools for assembly. However, they may not always offer a watertight seal.

Threaded connectors are more secure but need proper alignment. A recent report indicated that nearly 30% of users face issues due to incorrect installation.

Snap-on connectors are popular for their quick-release feature, yet they can wear out faster under heavy use.

In the agricultural sector, 45% of professionals prefer durable materials like brass or stainless steel. These materials resist corrosion and enhance longevity. However, they come at a higher price. Users must also consider the diameter of the hose when selecting a connector. Not all connectors fit all hose sizes. Sometimes, choosing the wrong size leads to leaks or breaks. This oversight is common but often avoidable with careful measurement.

Choosing the right hose connector can feel overwhelming. Understanding your specific needs is key. Start by evaluating the type of hose you have. Is it for water, air, or chemical use? Each application requires different materials. Match the connector to the hose type.

Consider the size. Measure the hose diameter closely. A loose fit can lead to leaks. A tight fit can cause damage. Take time to measure twice. You don’t want to go back to the store.

**Tips:** Always check the pressure rating. A connector must handle the maximum pressure of your system. Look for features like quick-release or swivel options. They can save you time and frustration. As you learn, remember that experimentation helps you find the best fit for your situation. You might make mistakes, but they lead to better choices later.

This chart illustrates the frequency of different hose connector types selected based on specific needs. Understanding these preferences can help you make informed decisions when choosing a hose connector.

When selecting hose connectors, material durability and compatibility are crucial. Various materials offer different benefits. For example, brass connectors resist corrosion, making them ideal for outdoor use. In contrast, plastic connectors are lightweight and rust-resistant but may not withstand high pressure.

A study by the Hose and Connector Industry Association notes that approximately 30% of hose connector failures arise from material incompatibility. Choosing a connector that complements your hose material can prevent leaks or bursts. Ensure that the connector’s specifications match your hose’s requirements, especially under extreme temperatures.

Compatibility extends beyond just material. Consider the specific fluids or gases. Some connectors deteriorate when exposed to certain chemicals. This leads to cases where users face unexpected failures. Always consult compatibility charts to make informed choices. The reliability of your connections often hinges on these small yet significant details.

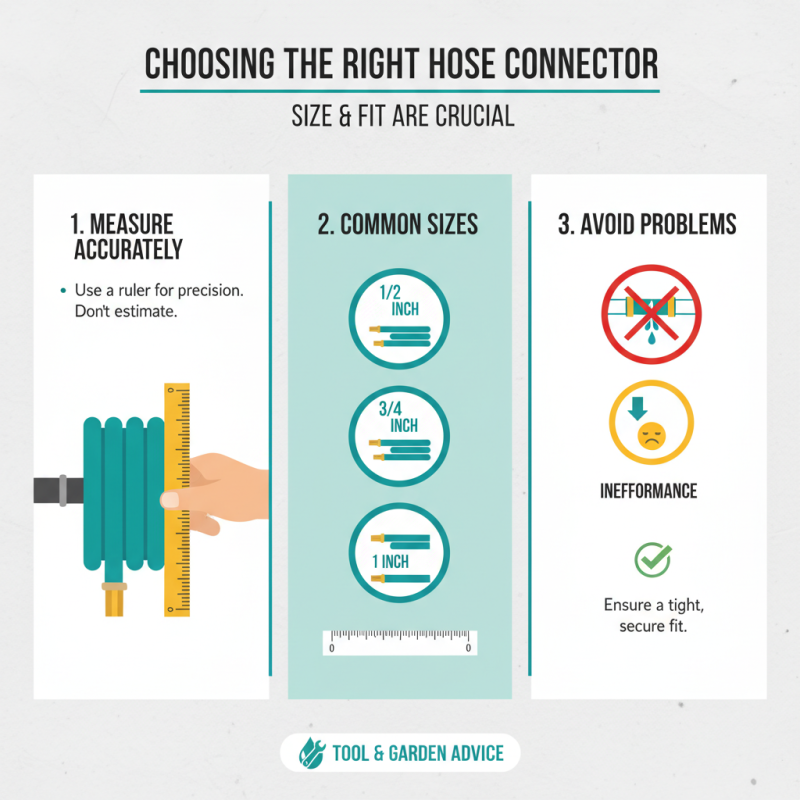

Choosing the right hose connector requires careful consideration of size and fit. A mismatch can lead to leaks or inefficient performance. Measure the diameter of your hose accurately. Common sizes include 1/2 inch, 3/4 inch, and 1 inch. Don't just estimate; use a ruler for precision.

It's essential to think about the material of the connector. Plastic connectors are lightweight but may crack in extreme weather. Metal connectors often provide durability but can corrode over time. Ensure that the connector you select matches the type of hose you have. Pay attention to the threading as well. Some hoses require specific threading types for a snug fit.

Always consider your specific needs. For instance, if you use your hose frequently, a robust connector is vital. Less frequent use might allow for a lighter option. Reflecting on your habits can guide your choice. Remember, a good fit prevents frustration and saves water. Assess carefully and take your time; this choice impacts your entire setup.

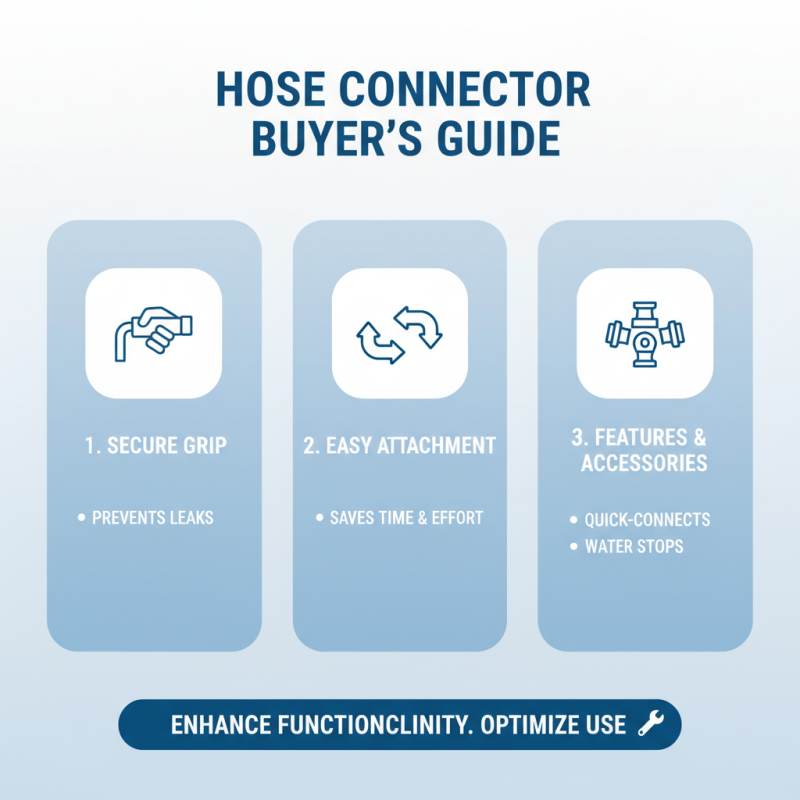

When selecting a hose connector, consider various features and accessories that can enhance its functionality. Look for connectors that offer a secure grip. This is essential for preventing leaks during use. Easy attachment features can save time and effort as well.

Some hose connectors come with adjustable fittings. These allow for compatibility with different hose sizes. This flexibility can be useful, but it might also create confusion. Check the specifications carefully to ensure a proper fit. Some connectors include additional features like built-in shut-off valves. They can help control water flow efficiently. However, they may complicate the setup, requiring extra attention when installing.

Accessories such as adapters and quick-release systems can also play a crucial role. While they can improve versatility, they may introduce more parts that can malfunction. It's important to consider the quality and durability of these accessories. Higher quality options can provide longevity, while cheaper alternatives may need frequent replacement. Balancing functionality with ease of use is key when choosing the right hose connector for your needs.